We've been expecting you!

The focus Blue Ocean team places on accountability, advisory, coaching and consulting, assist's individuals, projects and companies improve value, reliability and performance.

Book a FREE 30 minute discussion

Lean Construction

Blue Ocean has more than 3 decades of experience in lean transformation and change management for businesses and projects at a national and international level.

As capital projects become increasingly complex and dynamic, traditional approaches to management are not able to address the inherent challenges.

Our clients are gaining uncontested advantage by improving the delivery and management of capital assets. Working with owners, designers, operators, constructors, and suppliers across all construction industry sectors.

As a company that operates in a global capacity, when engaging with our clients our objectives are fundamentally the same – to add value and increase the reliability of delivering the project on time and within budget, safely.

From an initial workshop, into a demonstration project, through to hands on deployment and coaching, our skills are diverse and are geared to meet the expectations of our clients.

“In recent surveys of major projects, nine out of ten had cost overruns, cost overruns of 50 to 100 percent were common, and overruns above 100 percent were not uncommon”

“Design by Deception: The Politics of Megaproject Approval”, Bent Flyvbjerg, Harvard Design Magazine, no. 22, pp. 50-59, 2005

“Between 40 and 50 percent of all construction projects are running behind schedule… same as previous years”

Construction Management Association of America (CMAA), “6th Annual Survey of Construction Owners”, 2005

“1/3 of every dollar spent on construction is wasted”

Construction Users Roundtable (CURT) study, 2000

Our knowledge on project delivery can be applied to all projects facets within the industry. We work across all construction phases including: Project Definition; Design; Supply; Assembly; and Use / Decommission.

What we offer our clients:

If you were asked to make improvements of up to 50% on quality, cost and delivery ......Could you?

Blue Ocean’s view is that the prevailing wisdom regarding project management essentially abstracts away from the management of production.

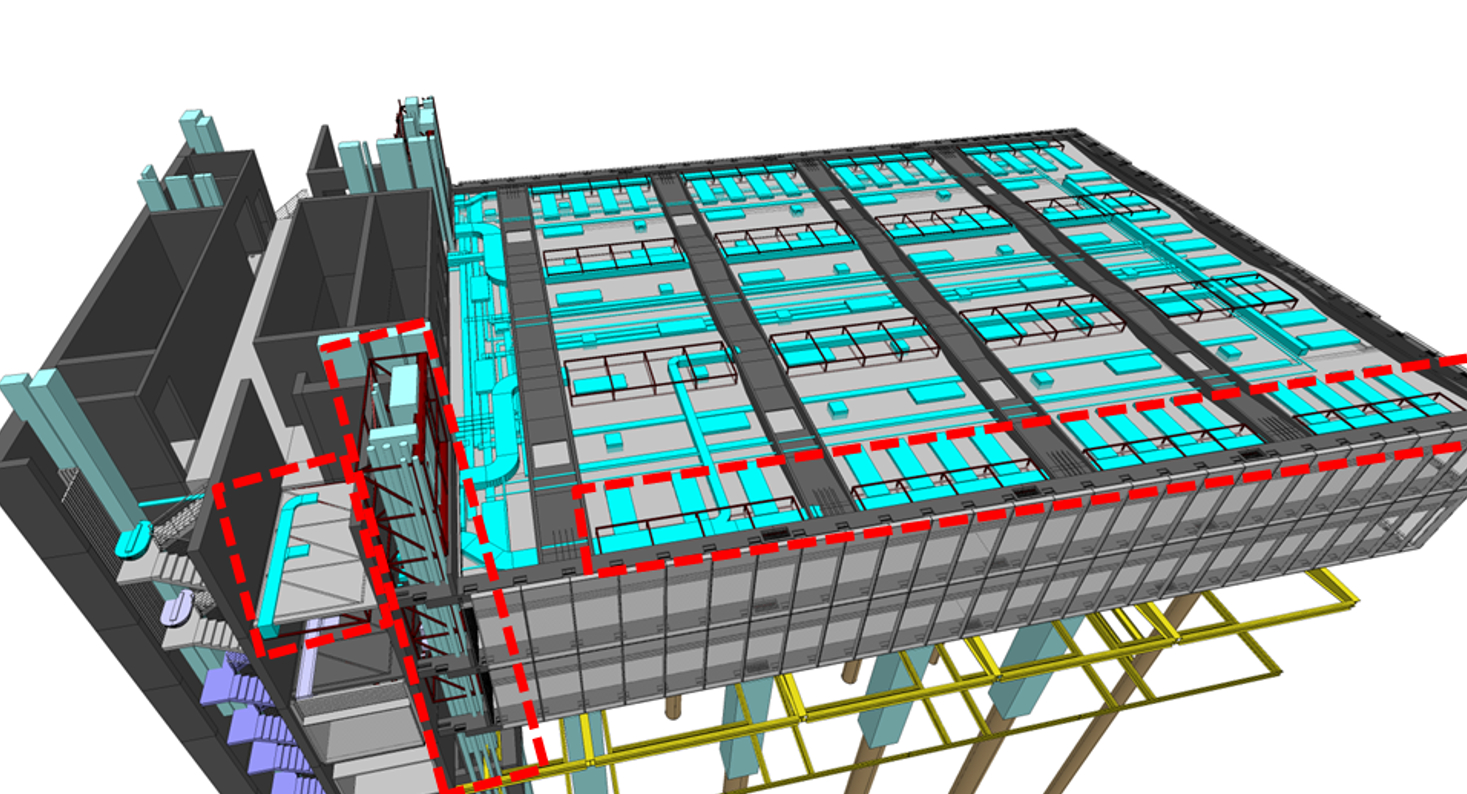

Digital Design & Prototyping

- Set-based concurrent design

- Digital builds and product lifecycle management

- Virtual reality and visualisation of process representation (down to execution level detail)

- BIM Coordination

- Construction Simulation

- Design Synthesis

- DfMA (Design for Manufacture and Assembly)

- Target Value Design

- Build'ability

- Clash Detection

- Real time costs and time

- Material and Logistics management

- Optimize labour and plant

Production Management & Control

- Deployment of the Last Planner System™ of Production Control

- Definition and design of the project as a production system

- Design look-ahead plans that are based upon making work ready

- Minimise workflow variability and to increase site pull to minimize project production system inventory

- Definition and design business processes and rules that support work execution

- Design execution level work plans on a weekly/daily basis through coordination meetings involving key stakeholders

- Deploy our web based enabling system [P2IC™] which enables greater business intelligence (where practicably possible)

- Definition and design of key measurements and analytics required to measure the project production system

Supply Chain, Material Management Integration & Optimisation

- Definition and design of material flow and management

- Definition and design of logistics centers

- Definition and design of site stores and consumables

- Knowledge management

Virtual Reality & Artifical Intelligence

- Dynamic reports and dashboards

- Templates for everyone

- Development workflow

- Limitless business automation

- Knowledge management

- Data capture and manipulation